I had hoped to find a metal gas can for my steam box boiler, but could not find one locally (they are all plastic), and though they are available online, the price ($40-50) was more than I wanted to pay.

People also use pressure cookers, but they are pricy, unless you can find one at a garage sale. Helena and I sold our pressure cooker at a garage sale, not so long ago. Who ever thought I'd need it?

Someone on the wooden boat forum mentioned using a paint can, and Home Depot has new paint cans for sale for under $5, so rather than wait for spring and garage sales, I've decided to go with that for now. I can always upgrade it to a pressure cooker or whatever, when I find one 'in the wild', this summer.

The reason you want a pressure cooker or gas can or paint can is the boiler needs to be a closed vessel, so the steam doesn't leak out. You could use a spaghetti pot or equivalent, but then you need to figure out how to seal it and keep it sealed during the steaming process. A normal pot lid doesn't seal the pot sufficiently.

To make sure the paint can bottom can hold up to an hour's boiling, at least, I'm going to do a test boil. I'll also try to determine how much water is boiled per hour, by checking to see how much water is left after an hour.

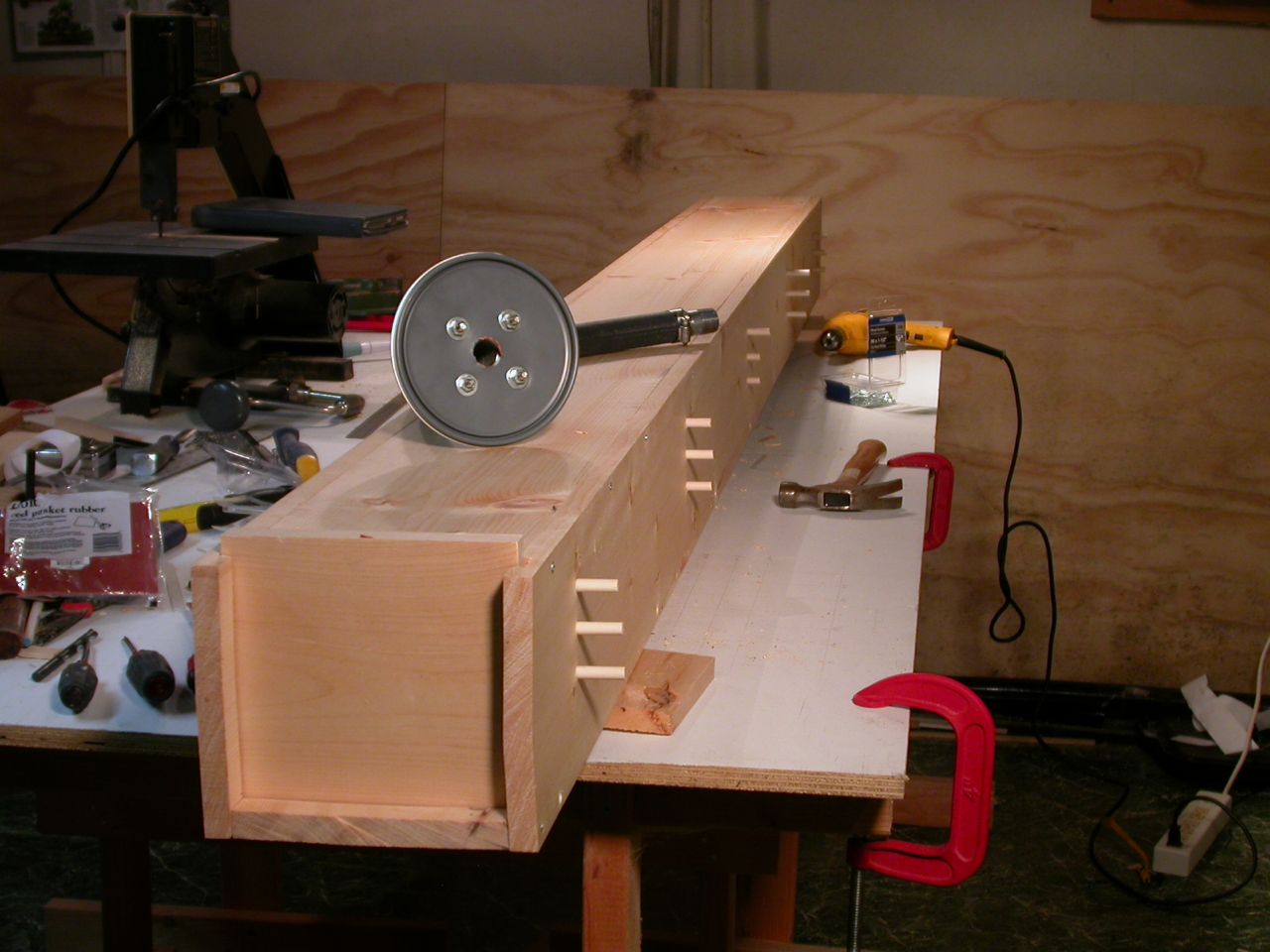

But here are some pics of the basic set up.

First, you need some sort of flange to attach the hose to both the can and the box. A correspondent to this blog, Jono, tipped me off to this common plumbing fitting:

|

| Flange & material for gasket |

Here is the lid, gasket, and flange ready for assembly.

|

| lid, gasket, flange |

And the whole boiler assembled, with hose clamped on.

|

| Assembled boiler |

|

| Steam box buttoned up |

Several correspondents warned me that my box would swell, jamming my cute little door shut, thus trapping my hickory inside and over cooking it.

To avert this tragedy, I opened up the dados that the door dropped into even more. Since a few people wrote to ask about my homemade router plane, I made a quick video, showing it in action.

Basically, what I've done is move the blade so it cuts about 1/8" deeper than the original dado. The blade is adjusted by loosening the wing nut on the back. I've already widened the width of the dado by about 1/4".

I do about 90% of the work in the first few seconds, then take another minute to get the corners sharp and clean. That seems a bit long to me, as I watch the video, but I was showing off for Helena!

I'm still practicing with this great little tool, so imagine I'll be quicker and less fussy as time goes on.

The results are quite good!

Anyway, back to the boiler. I know that some will consider doing a test run a bit nerdy... after all, this isn't NASA doing a test burn on one of their rocket engines, but what can I say? I'm a nerd at heart.

|

| Rocket scientist at work |

The results of an hour's test 'burn' are happily undramatic:

First, the can seemed unaffected by the hour's boil. It certainly didn't melt down, and frankly, I don't see any damage whatsoever to it. I imagine it will be good for at least several boils, as long as you don't let it run dry.

Second, a gallon was more than enough water for an hour. There was about 1/3rd of a gallon left. If I needed to do a two hour steam, I'd boil up another gallon in a kettle on the stove, and quickly refill my little boiler. I don't think it would take more than a minute to refill, which wouldn't have much effect on the steaming process.

Third, the boiler makes a huge amount of steam. You can see the plume in the background of the photo above. I think the 1" hose helps in this department. You don't want to do anything to impede the steam.

So, I do believe I'm ready to do some steaming. The next step is to build the forms to bend the steamed wood around.

>>> Next Episode: Whole Lot of Hectic

I have 2.5 gal and 5 gal paint cans lying around... but then, I never throw anything away. My wife says it is a mental illness...

ReplyDeleteThe steam box and steamer look like they will work great!

Good looking router. I use an old Stanley #71 for similar jobs. The larger size of yours seems to give you good control. Sometimes the stanley feels like it could use a little more mass or weight to feel right. Waiting to see the steamer in operation. Another video perhaps?

ReplyDeleteThanks.

A 2.5 gal can would probably be perfect. Plenty big enough for any steaming job.

ReplyDeleteYes, the router is terrific. The limitation in the video is the 'workbench' the board is clamped to. If I put too much strength into it, I would have pulled the bench off the floor. You can see me stepping on the saw horse to keep it from moving. On a real bench, the work would go a lot faster.

ReplyDeleteI've been playing around with my iPhone 4s, which makes doing video a lot easier. I just need to have my camera woman around.

Be aware that the steam condenses. I did my little steambox under a little tilt, so that the condensed water could leave the box. Nice job your box and boiler-can.

ReplyDeleteGood point. That's one of the reasons I screwed cleats on the inside bottom of the box. They will keep any stock off the bottom of the box, out of any accumulated water.

ReplyDeleteOf course, they will also impede the draining of the water a bit, but I don't think that should be a problem. I suppose I could drill small drainage holes, if it's a serious issue.

As a boiler operator, I really admire your set up..A bit of trivia for you, your water expands 17,000 times in volume when converted to steam. Keep up the great work....Allan

ReplyDeletegreat post

ReplyDelete