I didn’t have long to wait. He was already at it when I arrived mast-side at 9am, looking for both the source and extent of the rot. The good news: the mast had definitely been soaking up water from the deck. The further up the mast, the dryer the wood.

Also good news: I didn’t swoon while watching this surgery take place. With every handful of wet wood dug out, we got that much closer to having a sound mast again.

At least, that’s what I told myself.

|

| Looking for the extent of the rot |

|

| With all the rot removed |

After a consult, we decided that the old repair should be cut away, so that there was just one repair, properly done.

|

| With some previous repairs removed |

After cutting more old wood away, Dave discovered not one but two more previous repairs, one a 'Dutchman's scarf' using some sort of white wood, like pine.

If we left all these scarf in place, there would be 6 scarfs, all within a foot or so of each other. Clearly not acceptable, so he kept cutting.

Finally, all the old repairs were exposed and removed, and the demolition phase was over. Mostly.

|

| With even more (but not all!) previous repairs removed |

The long side in the photo above actually has three scarf in it, but Dave left it in place as a guide and support for the repairs. When replacing the compression core (photo below) he inserted wax paper between the long side and the core so that the epoxy would not glue the core to the side. This would make removing the long side easier later.

|

| Demolition phase (almost) complete... reconstruction begins |

|

| Reconstruction continues... |

And here is with that final, long side completely removed. We cut it high enough so that we could see above the compression core, into the inside of the hollow mast, above the core. As we'd hoped, it was bone dry, and the old core (with black Resorsinol glue showing) dry and sound.

Phew. This confirmed that the leak was indeed coming from the deck, and not from some where up the mast.

|

| The long-awaited look inside the mast -- all dry! |

The final scarf, for the final side.

|

| Fourth side and all old repairs removed |

And the whole repair glued up.

|

| Final side scarfed in |

|

| Shaping already in progress! |

|

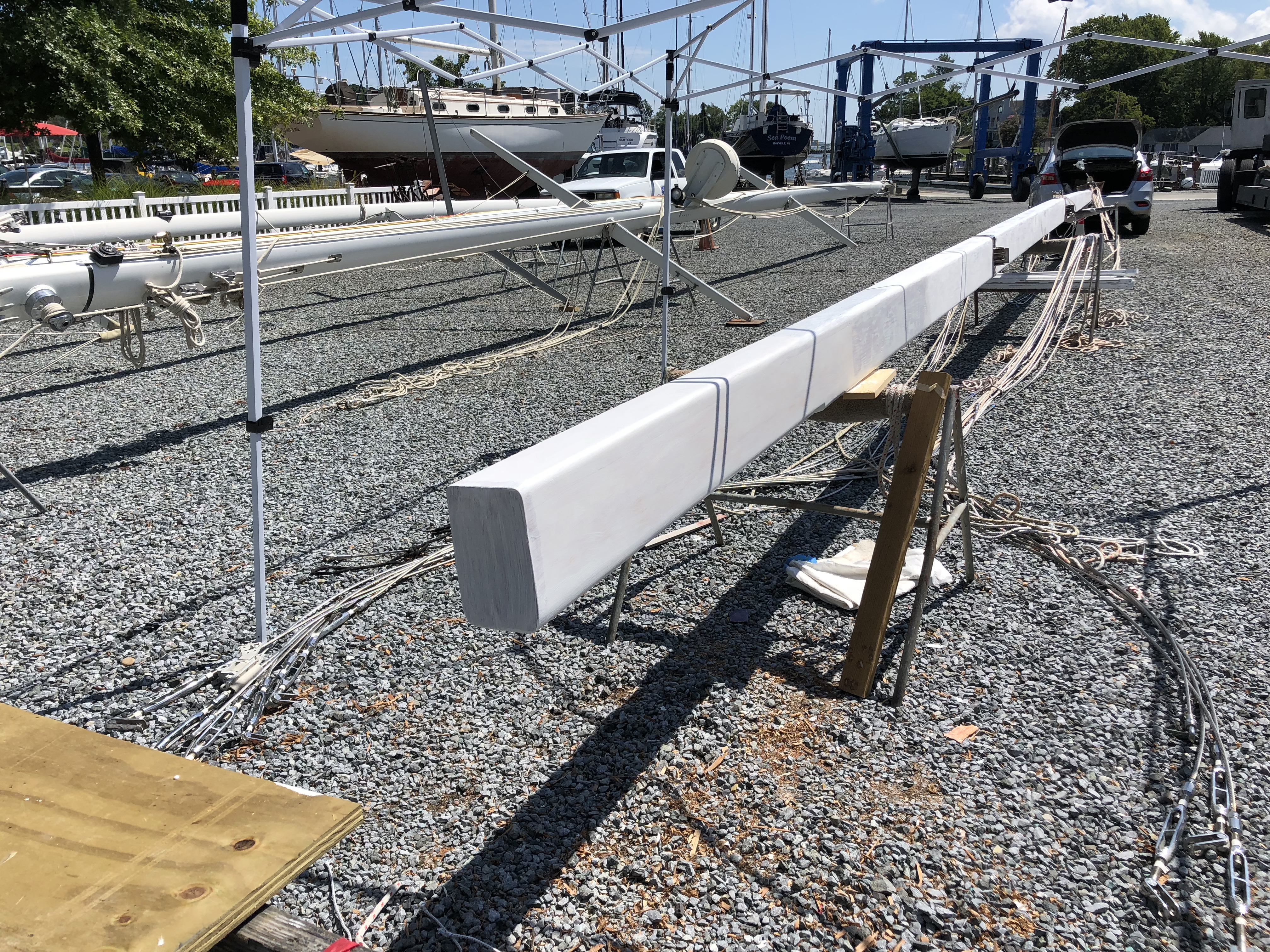

| Repair complete! |

And then it was time to paint. Since the mast already was painted with a 2-part epoxy paint, I decided to stick with that, although the prep work for it is crazy.

Here it is with the first coat of 2-part epoxy primer. It doesn't look like it, but I was racing a thunderstorm, so it was a big relief to get that first coat of paint on.

| |

| First coat of 2-part epoxy primer on! |

More on that adventure, later...

Next Up: Hiding from Florence

Merry Christmas John. Hope your mast and other repairs went as you wished and you and Helen have a very Merry Christmas and a healthy, happy and prosperous New Year. Fair winds and following seas, sir!

ReplyDelete