So, skipping all the jobs that involved a scraper, sandpaper, or paint, here are some of the more interesting projects we've finished in the last two or three days:

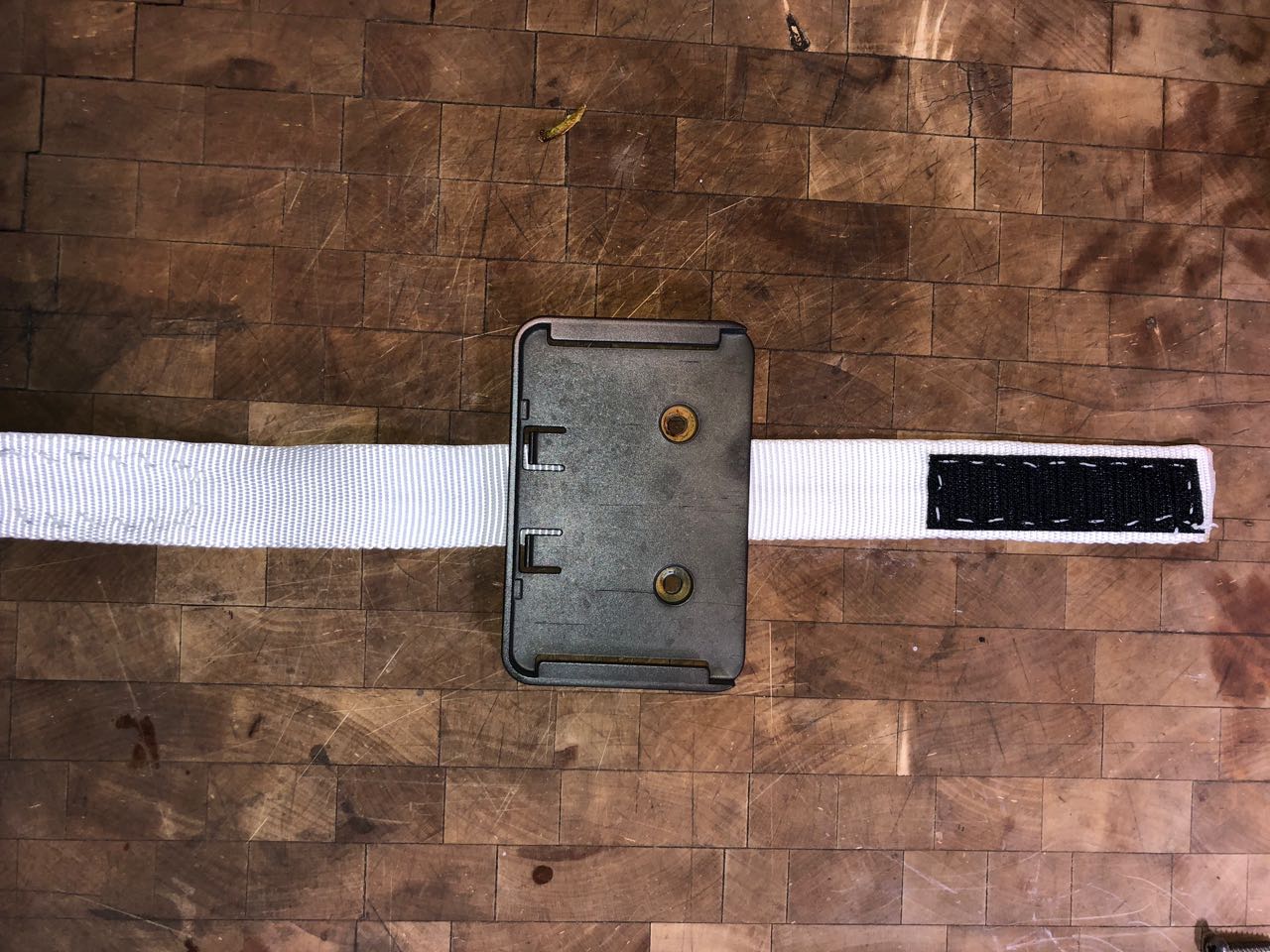

Strap for Iridium Go

Last year we got an Iridium Go to allow us to get surface charts and GRIB data quickly and easily. I'll be writing a lot more about the weather in the near future, but suffice to say the Iridium itself needs to be mounted so that it can see as much of the open sky as possible. A good way to evaluate positions is to put your eyes exactly where the unit would be and to see what you can see from that position.

This led me to the top of our boom crutch, which is about as unobstructed a position as I can reach from the cockpit. However, the mounting bracket for the Go is not the most secure. It was far too easy to imagine this vital bit of technology vibrating loose and pitching overboard. Thus the need for a little 'seatbelt'.

|

| Iridium Go 'Seatbelt' |

.I hand-sewed this one up from a bit of webbing and some velcro patches. Simple, but easy to make. The strap goes under the mounting bracket, which is screwed into the top of the boom crutch, and wrapped around the Go.

|

| It goes under the bracket |

This picture makes me feel a lot better.

|

| The Iridium Go in position and buckled in |

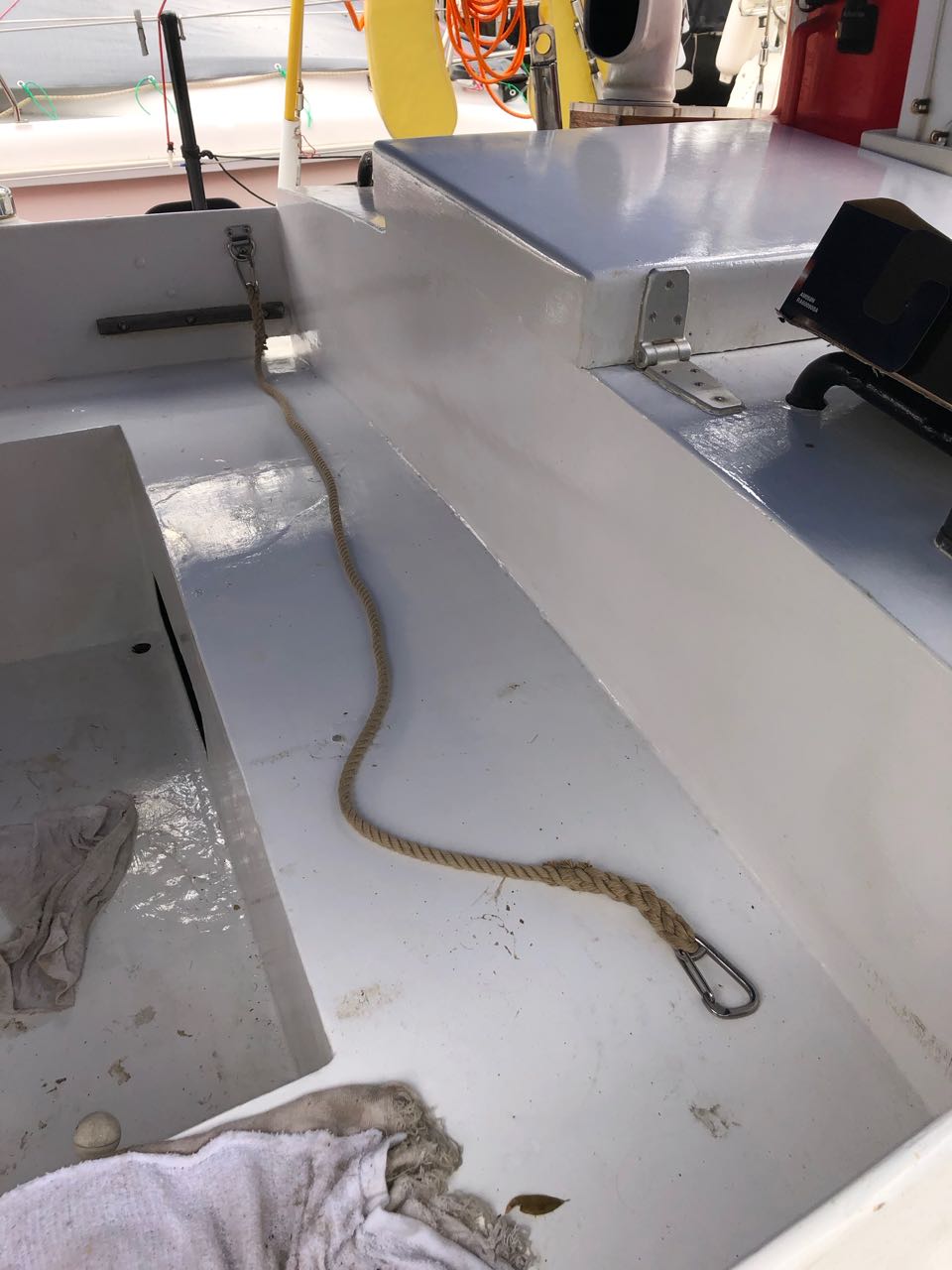

Second Cockpit Tether

Speaking of seatbelts, we always clip on while at sea, even in the cockpit. Yes, we do have a MOB procedure, but frankly, I never want to try it out. So we clip on.

After being caught in a night of gales off Cape Hatteras last year, I thought it would be a good idea to have a second tether in the cockpit. The idea is for the on-watch crew to clip in on the port side of the cockpit with his persona tether, and then to clip on to a second tether attached on the starboard side. This way, even if one of those monster waves found its way into the cockpit, it would be impossible to be washed out of the cockpit.

Overkill for the east coast of the US? Probably, but we are gearing up for an Atlantic Crossing next year, so it doesn't hurt to start thinking about really nasty storms.

|

| Spliced up from some dacron three-strand rope |

It's just long enough to reach comfortably across the cockpit.

|

| Second tether in the cockpit |

We've been doing some serious work in the cockpit (more on that in a future post), so we had the teak seats and floorboards out. Helena took the opportunity to give them some TLC by cleaning and oiling them. The seats are back in, but the floorboards will have to wait until we finish the cockpit job.

|

| Freshly cleaned seats, reinstalled |

We use a tri-color mast-head light for our main running lights. They are LED, so don't use much power and are very bright. However, the original running lights are still installed, and I like their classic looks. We like to think of them as our 'backup' running lights which, if you think about it, is not a bad idea. One problem: they didn't actually work. I decided to get them back into working order before our big trip.

|

| Classic-looking side light from the early 70s |

|

| Corroded lamp socket |

The stern light was more of a problem. Instead of a classic light, it was a cheap plastic LED light which was full of water. It still worked, but you'd be hard pressed to see it more than a few feet away. And unlike our 40 year old side lights, it was unrepairable. That should tell you something. I removed it and replaced it with a new, hopefully waterproof LED.

|

| New backup stern-light in place on back of the propane locker. We keep the SSR number just for old-time sake. It probably isn't legal! |

Gosh, you see the problem. I'm only halfway through the list of projects I wanted to write about, and already this post is too long. I will resume tomorrow, but meanwhile I will have completed a few more jobs. It really is impossible to keep up!

More tomorrow...

Next Up: A Further Taste

In my opinion, backup stern-light waterproof LED should shine 135 degrees on the horizon. To do this, it must be rotated so that the fastening screws are arranged vertically.

ReplyDelete