As part of Petronella's restoration, we are re-bedding much of her deck hardware. The first project was P's main sheet winches, under which rust was beginning to appear. Howdy and his crew removed the winches from their steel pads, and added disks of Starboard, which is a wood-like marine-quality material that doesn't rot. I think it must be some sort of plastic or fiberglass. Anyway, they bedded that down well to the steel, and mounted the winch on top. That will prevent rust from developing under the winch in the future, or for at least a long time.

|

| Winch re-bedded on Starboard pad |

The boys decided that P's granny bars needed to be-bedded, as some slight rust-stains were beginning to appear around one of the legs. Since the safety bars were through-bolted to the deck, that meant taking down the ceiling under the deck. They decided to give me that job (to keep me out of the way, I think!)

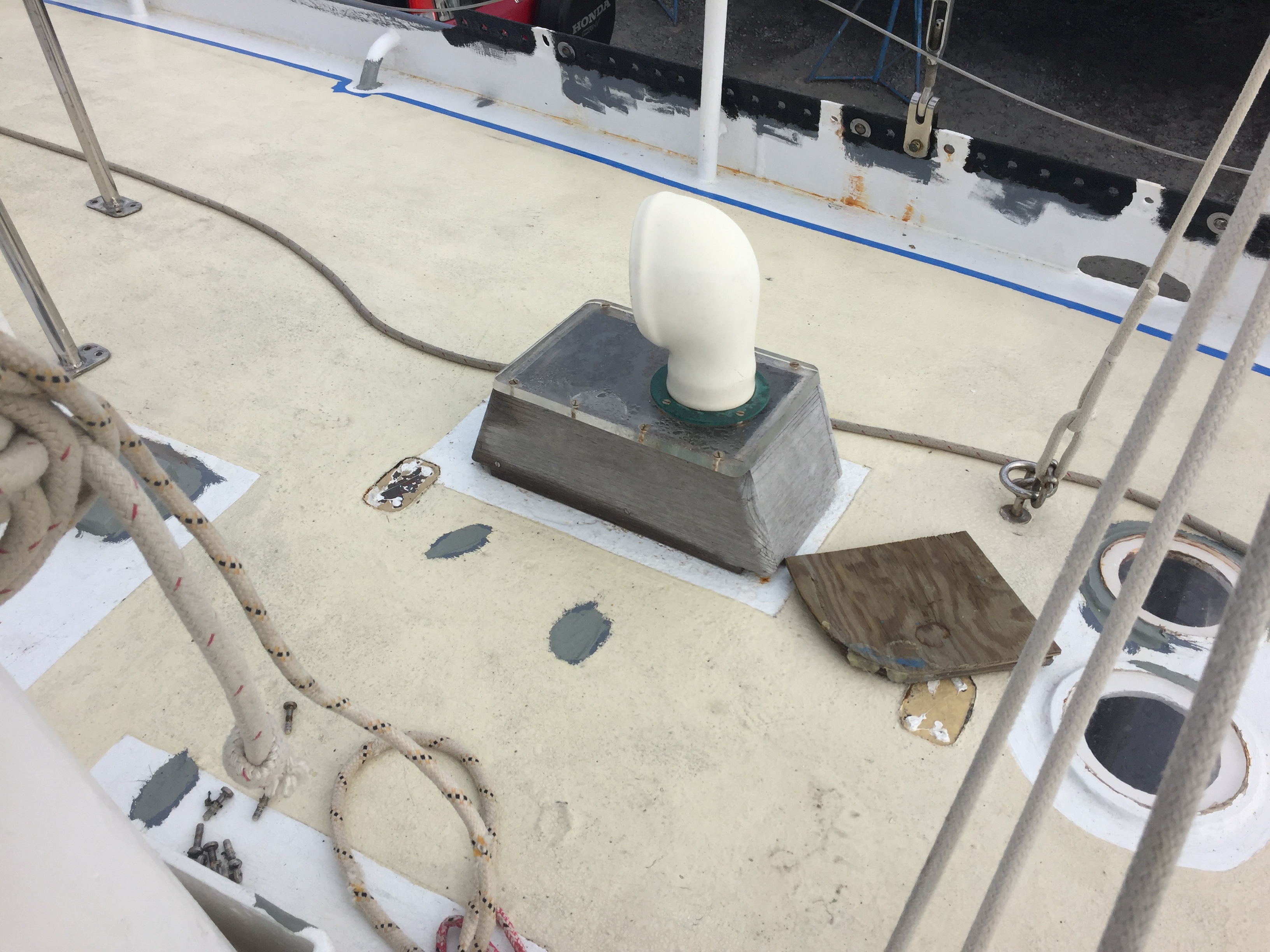

Petronella's ceiling unscrews quite easily, though it's a bit of jigsaw puzzle to put back up again. I soon had the required panels down, and that's when I spotted some rust developing around the vent hole of one of the Dorade vents.

|

| Granny bars removed. |

|

| Dorade vent, above deck |

|

| Around vent hole, under deck |

Under the vent, some water or moisture gathered around the vent hole, and made some rust. Now, this is slow progress... this spot has probably been rusting for many, many years. There was plenty of steel left, so no need for surgery, but as long as the ceiling was down, it was a good opportunity to stop the rust in it's tracks.

The first step was to remove as much of the surface rust as possible. I did this with a scraper, followed up by a cup brush mounted in my portable drill. That got 95% of the rust off. (A drop cloth plus dust mask and eye protection protected both the boat and me from most of the debris.)

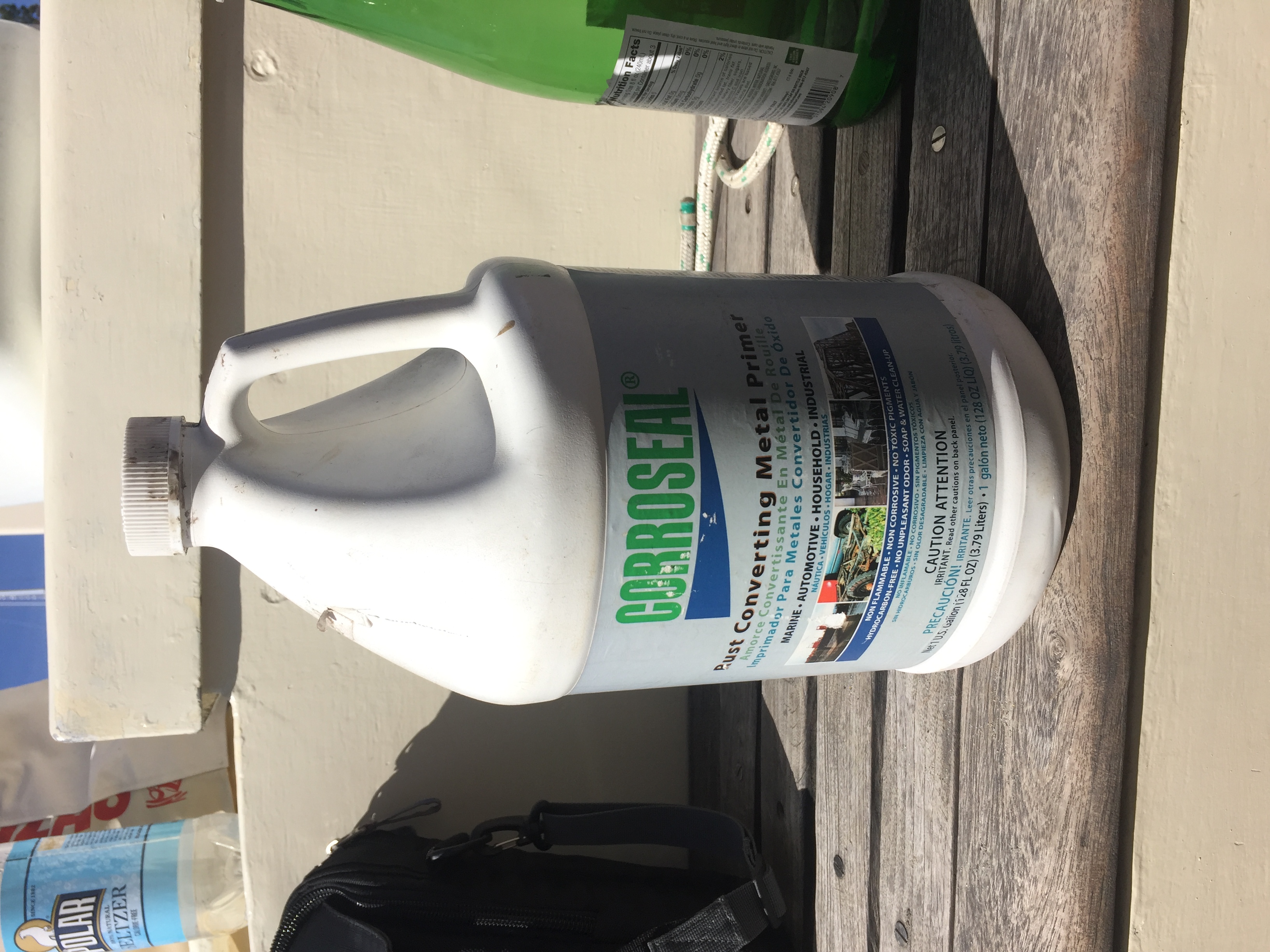

The second step was to hit the rust with one of the many 'rust converters' on the market. These products chemically convert the iron oxide into a material that purportedly acts as a primer. You do not remove the converted rust. You just leave it on and prime over it. Howdy likes a product called Corroseal.

|

| Rust converter |

|

| Rust after conversion |

|

| After first coat of Bar-Rust |

Next Up: More Rust Prevention Tricks

What your doing is wonderful. The boat is becoming new again and will serve you well for many years to come.

ReplyDeleteThanks, George. I’m real excited about how this project is turning out. Learning everything I can from Howdy. He’s demystifying the process for me.

Delete