Like the afternoon my friend Tony and I sailed her upwind into a tiny little gunk hole, making short tacks through the narrow channel, just like a real Coot, finally dropping anchor in a quiet little pool with the satisfaction that comes from leaving the engine off.

Or the time we sailed her into Huntington Harbor, through the narrow entrance, up the long channel, through the crowded mooring field, and right up to the mooring. Sweet.

It's little moments like that that make all the work worthwhile.

I wasn't completely idle in the shop. After building my jack plane, I finally understood enough about how wooden planes work to tune up my old smoothing and jointer planes. The secret was getting their soles dead flat, cleaning up the wedges (to keep shavings from jamming under them), and getting a sharp edge on the blade. They worked so well, I even took some fine steel wool and linseed oil and polished the accumulated grime off them. Now they work and look great, if I do say so myself.

|

| My trio of bench planes |

One day, when I was looking balefully at the jib sagging off to windward, I decided I needed one more piece of gear, and I even knew what I needed: a handy billy.

|

| Handy Billy with one end hitched on to the jib halyard |

|

| And the other attached to an eye-pad on deck |

To build some blocks, I needed some wood. I happened to have some teak that I salvaged from a rather nice teak table. The teak itself was still in great shape, but the fastenings used in the table's construction were, well, I think crap is the technical term. So the table fell apart.

|

| Teak in my scrap pile. |

Then I needed some sort of wood to make the sheaves from. The ideal wood for this is the rare and expensive Lignum Vitae. I bought a 2"x2"x8" blank of the good stuff on the Internet.

|

| Lignum Vitae (top), Teak (middle) |

Long time readers may remember my previous forays into block making. The Mark I and Mark II blocks are better left forgotten, but my Mark III block wasn't all that bad. In fact, it is still hard at work as the outhaul tackle for my mainsail.

|

| The Mark III block, still hard at work. |

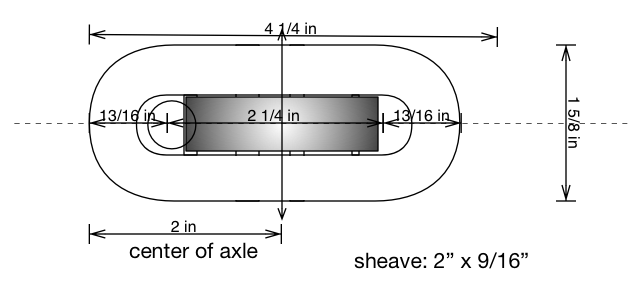

Since the dimensions would largely be set by the pieces of wood I had available, the plan was pretty straightforward to draw.

|

| Mark IV block plan |

So, with wood and plan in hand, it was time to start making sawdust.

Next Up: A Better Mortise

Oh come on ... you leave us hanging? Love it so far though

ReplyDelete